By Misagh Tabrizi

As the demand for data storage grows, data centers are becoming increasingly prevalent. However, their rapid expansion brings challenges, especially concerning noise and emissions from mechanical equipment and generators. Fuel choice and regulatory compliance are crucial in selecting appropriate after treatment technologies to meet emissions and noise requirements. This article delves into the EPA (Environmental Protection Agency) requirements for generator systems in data centers and explores effective emissions reduction technologies to meet these standards.

1.0 AIR EMISSION PERMITS

Data centers must comply with EPA and other applicable emission standards to obtain air emission permits. Under the Clean Air Act, the EPA maintains the National Ambient Air Quality Standard (NAAQS). If an area’s air quality meets NAAQS for a pollutant, it is considered “in attainment” for that pollutant. Conversely, areas not meeting NAAQS are designated as “non-attainment areas.” States with non-attainment areas must develop a State Implementation Plan (SIP) to achieve NAAQS compliance. Generally, a data center’s generator system must adhere to EPA Tiers for NAAQS, but non-attainment areas face stricter standards. Therefore, understanding the specific standards is the first crucial step.

2.0 EMISSION COMPONENTS REGULATED FOR NAAQS

Regardless of engine type and fuel, the EPA regulates the following pollutants:

Unless otherwise required, most applications are needed to meet Tier4 standards for these pollutants as per the table below:

Tier 4 Standards for Engines Above 560 kW

| Category | NOx (g/kWh) |

PM g/kWh) |

CO (g/kWh) |

HC (g/kWh) |

|---|---|---|---|---|

| Generator sets | 0.67 (0.50) | 0.03 (0.022) | 3.5 (2.6) | 0.19 (0.14) |

3.0 ON-SITE EMISSION TESTING AND ADDITIONAL REQUIREMENTS

In some cases, on-site emission testing is required, either using the building load or a load bank. For example, an ambient air quality check might be needed in non-attainment areas before an air quality permit is issued. On-site testing often involves the EPA’s Atmospheric Dispersion Modeling (AERMOD) system, which simulates pollutant dispersion based on site topography, primary emission sources, prevailing winds, and other factors. Before such testing can commence, after treatment, devices must be installed and commissioned on generators.

In addition to NAAQS compliance, larger diesel engine applications in non-attainment areas must consider other regulations:

4.0 EMISSION REDUCTION TECHNOLOGIES

To reduce emissions, data center diesel generators can use various after treatment technologies:

Three-way catalysts (3WC) can reduce NOx, CO, and unburnt hydrocarbons for rich-burn natural gas applications. For lean-burn natural gas applications, SCR can ensure compliance with NOx standards.

With SCRs, the total cost of ownership can be significantly reduced if the SCR manufacturer provides an airless system that can eliminate the need for the conventional compressors that are typically used for delivery of the compressed air for DEF injectors into the exhaust. These airless systems have fewer parts, less maintenance, and less installation costs associated with their systems with comparable NOx reduction efficiency. An example of an SCR installation is seen in the image that includes a roof-mounted framework with a swing gate, safety rails & walkway (courtesy of IMS-EI Williams Industries.)

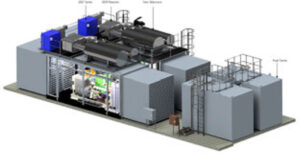

Since these emissions control devices create considerable restrictions on exhaust gases from the engine, it is crucial to carefully design the exhaust piping to avoid exceeding the engine’s back pressure limit. Choosing a supplier that offers a comprehensive, turnkey solution is typically preferred. Such suppliers can provide the entire exhaust system, from the engine flange through the after-treatment devices to the stacks and tailpipe. This approach helps minimize the overall restriction on the engine. Additionally, a single supplier can effectively manage engine noise reduction without over-engineering the system, making their solutions more economical. An example of a low back pressure emission and noise reduction system design is shown in the next picture (courtesy of IMS-EI Williams Industries.)

By implementing these technologies and adhering to regulatory standards, data centers can effectively address noise and emission concerns while supporting their growth and operational needs.

By implementing these technologies and adhering to regulatory standards, data centers can effectively address noise and emission concerns while supporting their growth and operational needs.

Misagh Tabrizi, P.Eng. is Engineering Director at EI Williams Industries. He can be reached at [email protected].