62

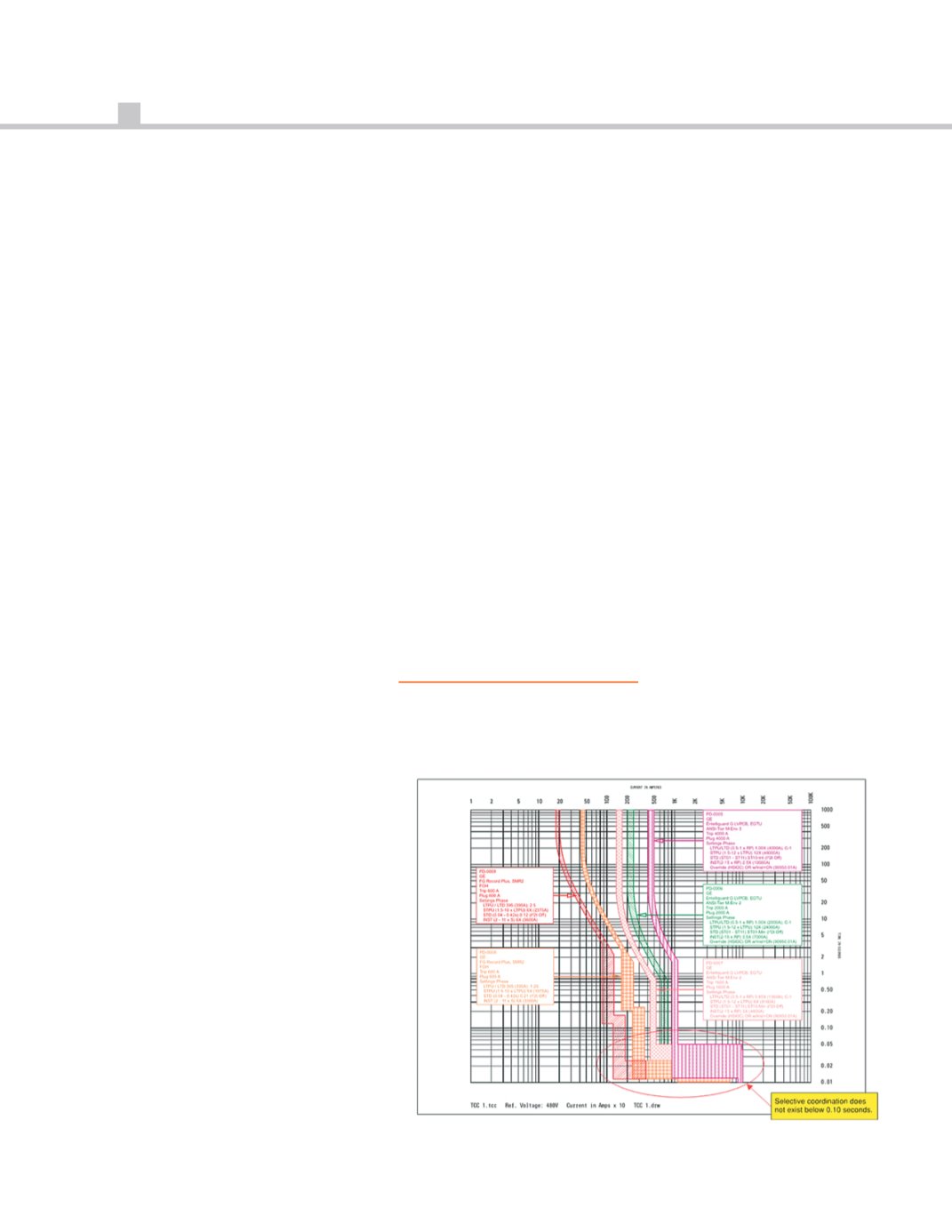

Traditionally, selective

coordination can be

accomplished by overlaying the

Time-Current Characteristic

(TCC) curves for each

overcurrent protective device

and adjusting their trip settings

to ensure the TCC curves did not

overlap. Selective coordination in

the instantaneous region (below

0.1 seconds) poses significant

challenges when modeling

similarly rated circuit breakers,

while simultaneously trying to

minimize arc flash incident

energy. Previous editions of the

NEC did not define specific time

or current parameters where

selective coordination must exist;

this resulted in many systems that

were coordinated only in the

short and long time regions

(beyond 0.1 seconds) or under

“bolted-fault” conditions in an

effort to avoid installing larger,

more expensive equipment.

For example, the typical 20A

circuit breaker is not selectively

coordinated with the typical

225A main panel board circuit

breaker. This is also true of many

molded case circuit breakers with

instantaneous trips. It will be

necessary to specify and select

different equipment and devices

to comply with this requirement

for selective coordination.

The

revised definition in Article

100 now states that selective

coordination

must include: “the

full range of available

overcurrents

, from overload to

the maximum available short

circuit current, and for the full

range of overcurrent protective

device opening times”.

Conventional TCC analysis may

no longer be sufficient.

Manufacturer selectivity tables,

which specify the relative

operating times of various circuit

breaker combinations, and other

techniques such as instantaneous

Zone Selective Interlocking (ZSI),

may be necessary to achieve

selective coordination in the

instantaneous region. According

to the NEC, ‘selective

coordination’ should not be

confused or interchanged with

the term ‘coordination’

referenced in other code articles,

such as 517.30(G). Coordination

refers only to “the period of time

that a fault’s duration extends

beyond 0.1 second”.

arTiCle 646: modular

daTa CenTers

Modular Data Centers (MDCs), or

offsite constructed data centers,

represent a growing trend in

data center architecture. MDCs

are prefabricated units rated 600

volts or less, which are

preassembled at a factory and

shipped to the construction site.

An MDC may consist of one

module that contains ITE and all

supporting power and cooling

equipment, or it may consist of

multiple interconnected modules

with the ITE separated from the

supporting power and cooling

equipment.

MDCs offer several advantages

over traditional “stick-built” data

centers: they are constructed off-

site in controlled environments

and can be shipped nearly

anywhere in the world, enabling

accelerated project deliveries

and reducing project risk due to

weather or other unforeseen site

conditions. MDCs are inherently

scalable and provide greater

flexibility, with nearly unlimited

load-on-demand opportunities.

7X24 MAGAZINE FALL 2014

Typical TCC Curve used for Selective Coordination