42

7X24 MAGAZINE FALL 2014

Modular Containment has four airflow

management components.

1

Angular Rack Top Baffles.

2

Vertical Rack Top Baffles.

3

Bi-Directional Doors

4

Adjustable Rack Gap Panel

Angular Rack Top Baffle

Rack Top Baffles are typically installed on the top front

edge of an IT rack in a cold aisle. It extends from the

front edge of the rack into the aisle, reducing the

open area of the aisle and slightly pressurizing the

cold aisle relative to surrounding areas. In addition,

the Rack Top Baffles significantly reduce the

recirculation of hot exhaust air from the rack

equipment across the top of the rack and back into

the front intake of the rack.

Vertical Rack Top Baffle

Vertical Rack Top Baffles are typically installed on the

top rear edge of the IT rack and further restrict

hot/cold air mixing. They also separate the hot

exhaust air on the rear of the rack from the cold supply

air on the front of the rack, and create a chimney effect

that directs the hot air towards the ceiling plenum and

returns of the cooling units. The recirculation of air

over the tops of the rack is virtually eliminated. Vertical

Rack Top Baffles can also be installed on the front of

the racks in the cold aisle. In some computer room

configurations, this may provide a better solution for

air separation than the angular baffles.

Bi-Directional Doors

Doors at the end of the aisles are the third component

that further isolates the hot air and cold air mixing in

the computer room. In most computer rooms, hot

exhaust airflow wraps around the sides of the racks at

the end of an aisle. This results in significant mixing of

the hot and cold air, and elevated inlet temperatures

for the IT equipment in these racks. The usual

compensation for this is to add perforated tiles,

increase the cooling unit’s airflow volume, or decrease

the temperature set points. Though these

implementations often work, it is using a brute force

approach. Increasing fan speeds or decreasing

temperature set points has a significant impact on

electrical usage and energy costs. To incur these

inefficiencies for the sake of a few racks is a waste of

resources and compromises utilization.

Adjustable Rack Gap Panel

The final component to a Modular Containment

System is the Adjustable Rack Gap Panel. The

Adjustable Rack Gap Panel seals the space between

the racks when they are not adjacent to one another.

In many computer rooms, cabinets are not contiguous

in the rows. The gaps are often due to obstructions,

including support columns, variable width cabinets,

and cabinets that have been removed but not

replaced. The openings in the rows allow significant

bypass and or recirculation of the exhaust air.

Prevention of this improves overall computer room

efficiency and reduces hot spots at the rack level.

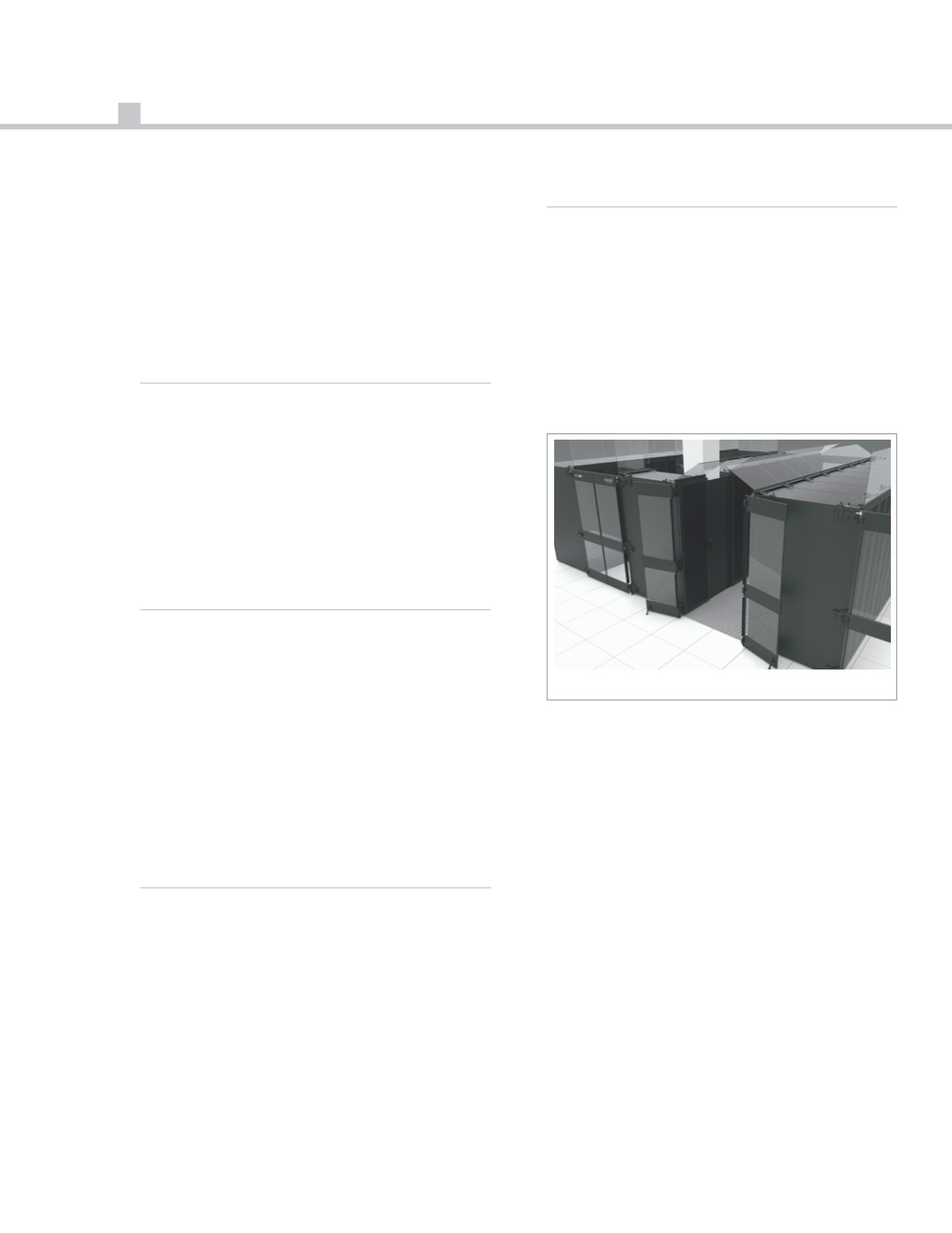

Figure 1 shows the basic principles of a Modular

Containment System. Containment in any computer

room is best attained when there is a structured hot

aisle/cold aisle layout. Specifically, when each

equipment row has an equal length so the ends of the

aisles can be effectively sealed with a pair of

Bi

‑

Directional Doors. While this is the ideal

configuration, significant benefits can be realized

from installation in other configurations such as a

single row aisle, standalone equipment, legacy layout,

rows of different lengths, etc.

Modular Containment is designed as a non-sealed

architecture for hot and cold aisle containment. A

non-sealed architecture is of benefit since there is

considerable variation in the volume of air required by

IT equipment. Even with highly refined airflow

management, a slight excess volume of conditioned

air is delivered to the cold aisle. This is primarily done

to accommodate variations in IT equipment airflow

volume demands. A slight excess airflow volume is

also the result of having redundant cooling capacity

running in the room so when a cooling unit fails there

is still a sufficient volume of conditioned air available.

If there is no opening for the excess volume to escape,

excessive pressure can develop in the cold aisle.

Fig. 1 – Modular Containment System