46

Modular Containment Field Results:

Basic Computer Room Architecture at a Global

Financial Institution

Layout:

n

Raised floor computer room.

n

25% open area perforated tiles in a four foot wide

cold aisle.

n

Down flow peripheral CRAH units.

n

Angular Rack Top Baffles in cold aisle.

n

Bi-Directional Doors on cold aisles.

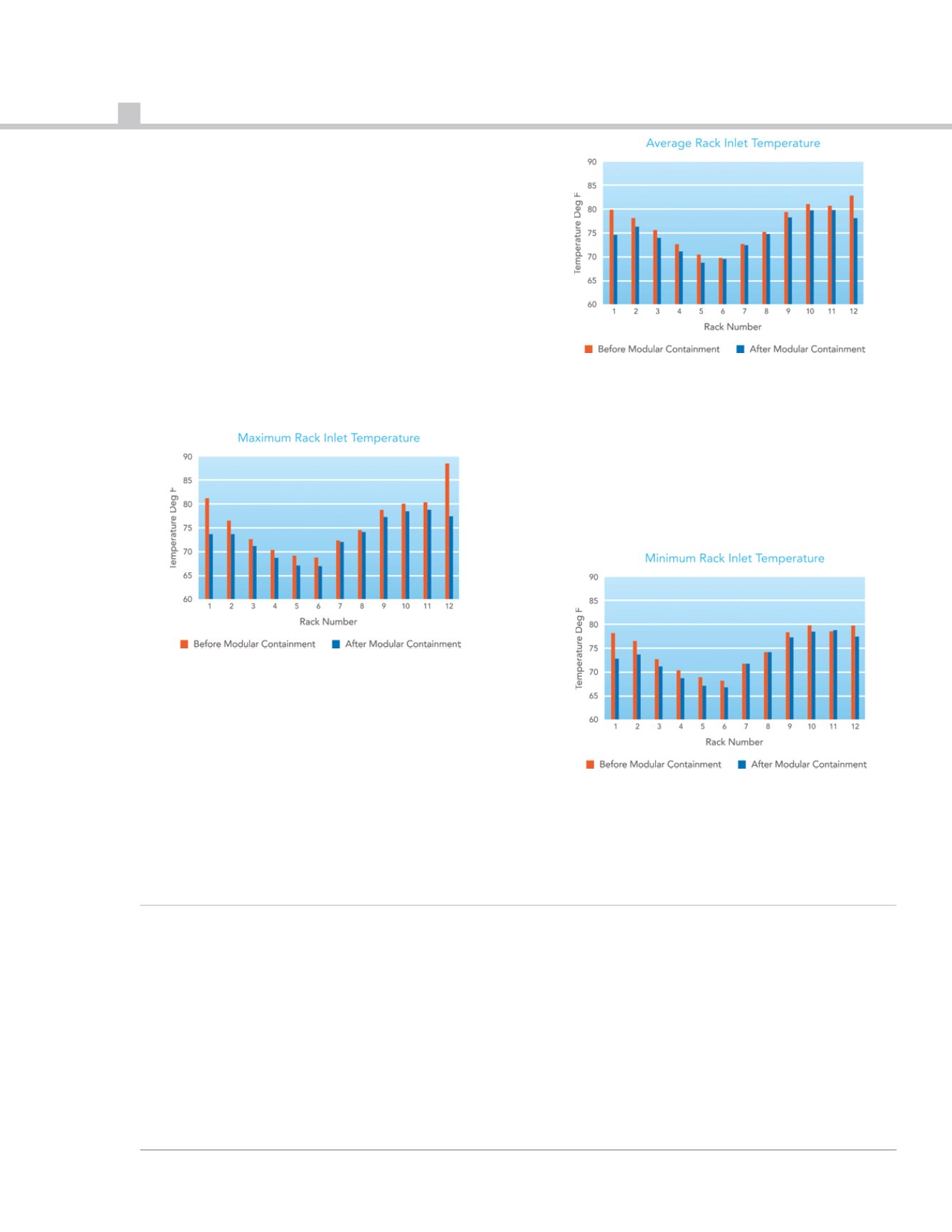

Figure 6 shows across-the-board maximum rack inlet

temperature reductions with the end aisle cabinets

showing the most significant decrease from

installation of the Bi-Directional Doors. The maximum

inlet temperatures occurred at the top front of the

rack. Recirculated exhaust air from back to front over

the top of the rack and around the sides of the end

racks was the major contributor to the increased inlet

temperatures.

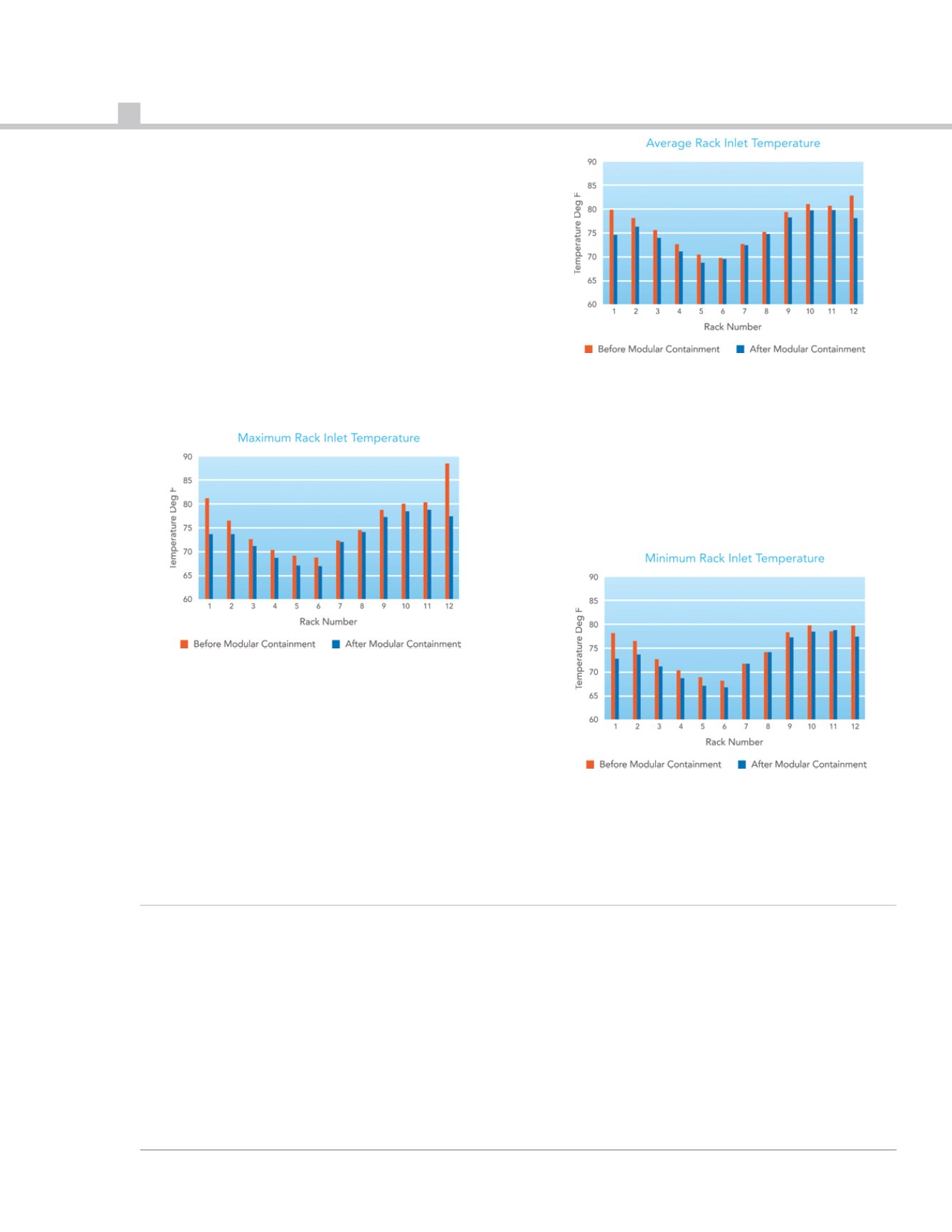

Temperatures were measured at four locations evenly

spaced from top to bottom on the front of the rack. An

average of these temperatures was used for each rack

in Figure 7, which shows how the application of

Modular Containment reduced average rack inlet

temperatures across-the-board. For this site, the Rack

Top Baffles and Bi-Directional Doors had less of an

influence in the center of the row, while the most

dramatic changes were at the end of the aisles.

When examining the impact of Modular Containment

to the minimum rack inlet temperatures, the results

further reiterate that the most dramatic changes in

temperature happen at the ends of the aisles.

7X24 MAGAZINE FALL 2014

Lars Strong is Senior Engineer at Upsite Technologies. He can be reached at

Fig. 6 – Maximum Rack Inlet Temperature

Fig. 7 – Average Rack Inlet Temperature

Conclusion

Prevention of hot and cold air mixing is a key to all efficient computer room cooling strategies. Modular Containment

effectively reduces the mixing of hot and cold air and creates an environment where substantial cost reductions can

be achieved, while also allowing for increased rack, row and infrastructure utilization. Modular Containment also

allows optimization to the configuration and operations of the computer room cooling infrastructure. This includes

changes to the cooling systems such as; raising chilled water set points, increasing both water and air side

economizer hours, reducing fan speeds, cycling CRAC/CRAH units, etc. The Modular Containment implementation

also has added value in significantly reduced installation complexity and costs, the ability to install in an existing

computer room without interruption to operations, and the flexibility to change the Modular Containment

configuration as the needs of the computer room infrastructure change. Other means of sealing both hot and cold

aisles include hard wall containment, soft curtain containment and other products on the market. Though these

products work well, they typically require a complex process of quoting, designing, customizing and professionally

installing, and are often unnecessary for the densities present in the typical computer room. Modular containment

provides a means to achieve similar containment results without the cost and complexity of full containment systems.

Fig. 8 – Minimum Rack Inlet Temperature