44

7X24 MAGAZINE FALL 2014

When this occurs, more air is forced through the IT

equipment than required by the equipment. ASHRAE

explicitly recommends against this condition of over-

pressurized cold aisles. The open-sealing architecture

of Modular Containment solves this problem by

containing cold air to the level needed while allowing

any excess volume to escape when required.

The Rack Top Baffles and Bi-Directional Doors install

quickly and easily without the use of tools. Moving or

reconfiguring these components is simple and does

not require special skills. The rack top vertical panels

work well in a traditional raised floor computer room,

but can also provide similar benefits in a slab floor

environment with dedicated cold aisle supply ducts.

In a flooded supply/flooded return environment,

caution should be used when installing Modular

Containment, or for that matter, any type of barrier to

airflow in the computer room. Disruption of airflows in

this scenario could cause inadvertent rack inlet air

temperature increases.

Modular Containment CFD

Analysis

Computational Fluid Dynamic (CFD) analysis has

shown that Modular Containment can achieve many

of the core benefits of traditional containment, such as

reduced inlet temperatures, energy savings, and

increased rack densities, but without the costs or

inconveniences that accompany the current

containment options. The major benefit of Modular

Containment is its ability to attain a similar level of

efficacy with a simple and cost-effective design.

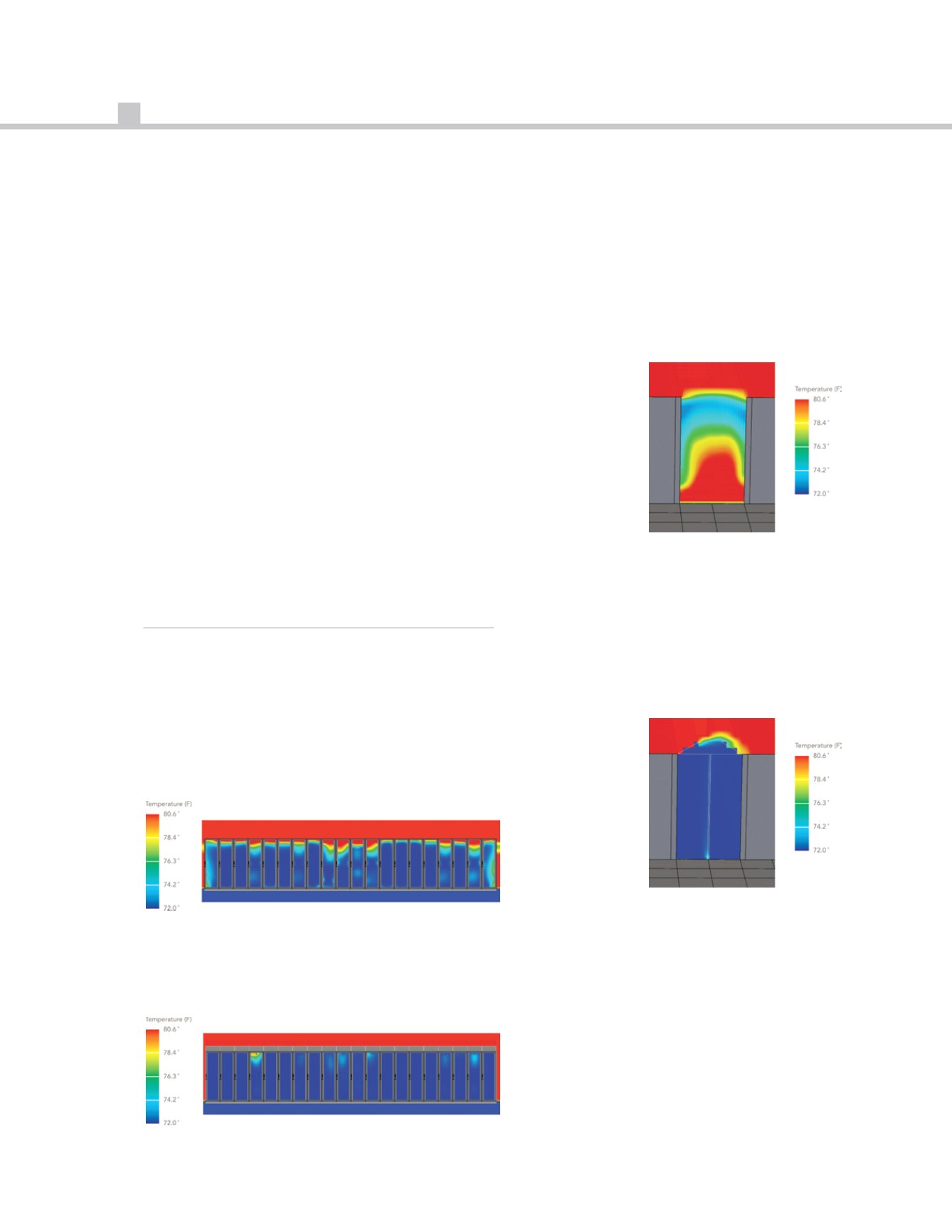

The CFD model shows significant recirculation of

exhaust air over the tops of the racks. The color red

indicates temperatures exceed ASHRAE TC9.9

recommended temperature of 80.6 Deg F.

With Modular Containment, the rack inlet

temperatures become very consistent top to bottom

and are all below the ASHRAE TC9.9 recommended

temperature of 80.6 Deg F. The maximum reduction

in rack inlet temperatures was 10.3 Deg F and the

average reduction in rack inlet temperatures was 3.7

Deg F. It is important to note the racks now have

uniform inlet temperatures. This enables further

optimization of cooling tile airflows and cooling unit

operational set point temperatures.

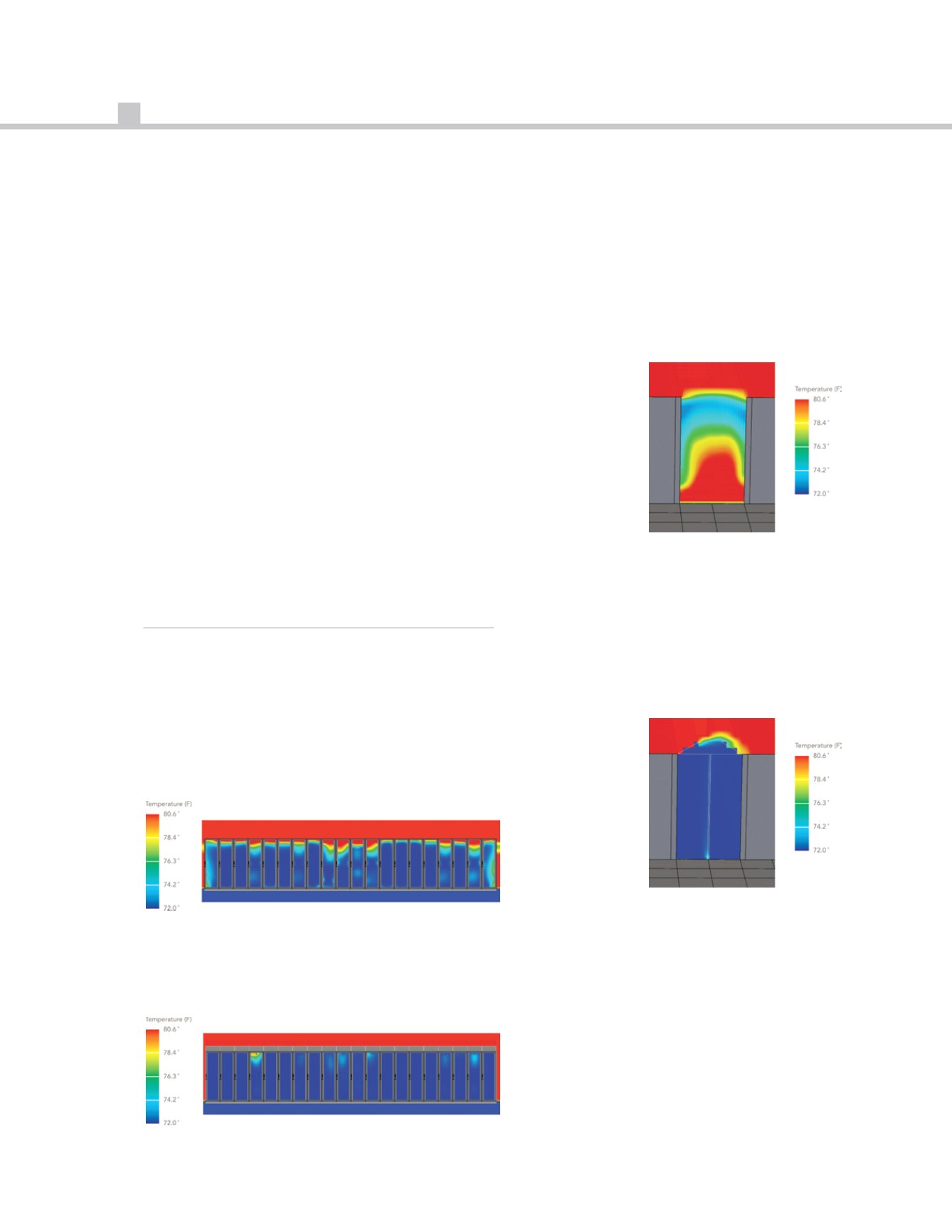

The CFD model shows significant recirculation from

back to front on the end aisle racks. Hot exhaust air

from the rear of the racks is wrapping around and

being pulled into the equipment inlet on the front of

the rack. The color red indicates temperatures exceed

ASHRAE TC9.9 recommended temperature of 80.6

Deg F.

With the installation of the Bi-Directional Doors, the air

recirculation around the ends of the aisles is stopped.

All IT equipment inlet temperatures now meet the

ASHRAE TC9.9 recommended temperature of 80.6

Deg F. For the aisle end cabinets the maximum

reduction in rack inlet temperatures was 10.2 Deg F

and the average reduction in rack inlet temperatures

was 6.2 Deg F. As before, the uniformity of the rack

inlet temperatures enables further optimization of

cooling tile airflows and cooling unit operational set

point temperatures.

Fig. 2 – Front View of Racks

Fig. 3 – Front View of Racks

Fig. 4 – No Aisle Containment (end view)

Fig. 5 – With Modular Containment (end view)