conditions, they can provide full

economizer operation to reduce

compressor energy consumption to

zero. This system eliminates water use

and the need to introduce outside air

directly into the data center. It also

cuts the maintenance costs

associated with dampers or louvers

and water treatment for most

economization systems.

The energy-saving benefits of

economization also extend to chillers.

Relying strictly on outside air, or using

free cooling in concert with other

technologies for heat removal,

dramatically reduces chiller energy

consumption and, in some cases,

water usage.

SAVINGS FROM

IMPROVING

THE LEGACY THERMAL

MANAGEMENT

SYSTEM ADD UP

Taking advantage of the

aforementioned thermal management

opportunities in a legacy data center

can make a significant difference in

the energy bill, as shown in the

example below.

Assume a legacy data center

operating under the following

parameters:

• 5,000 square-foot data center

• Direct expansion (DX) thermal

management system with 500kW

capacity

• Precision cooling in hot-aisle/cold-

aisle arrangement

• 75° F return air temperature

• $0.10/kWh energy cost

GET A HANDLE ON NEW

CUSTOM AIR HANDLING

TECHNOLOGIES

Typical standard rooftop air handling

units are simply unable to maintain

the precise temperature and humidity

control demanded by mission-critical

environments. However, custom air

handlers are now on the market that

have been designed specifically for

large data centers using evaporative,

chilled water or DX technologies.

Air handling units designed for the

data center can offer a level of

customization and flexibility needed

in these unique environments and are

typically used in data centers from 5-

30 MW or higher. The units usually

feature intelligent controls that

provide advanced protection and

enable air flow, temperature and

economizer function to be adjusted

automatically based on IT load and

ambient conditions. With these

control systems in place, the units can

work more efficiently and help data

center managers achieve annual

mechanical PUE under 1.2. As with

traditional data center thermal

management, advanced controls are

critical to successful operation. Many

of these systems can also be simply

integrated with building management

systems and DCIM solutions.

REDUCE PUE USING FREE

COOLING CHILLERS

As with custom air handling units, a

new generation of air-cooled chillers

has been designed specifically for

data centers and mission-critical

applications. These chillers use built-

in economizers, system optimization

software and state-of-the-art

components—for instance, advanced

controls, digital scroll compressors,

EC fans, microchannel condensers

and electronic expansion valves—to

deliver high efficiency (mechanical

PUE as low as 1.08) and high

availability.

Free cooling chillers contain built-in

redundancy, fast restart capability and

continuous cooling availability in case

of water shortages, extreme ambient

temperatures and unstable power

supplies. Free cooling chillers come in

units up to 400 tons in capacity and

are ideal for chilled water data

centers up to 6 MW.

POWER

INFRASTRUCTURE

If your data center runs on a legacy

power infrastructure, its weaknesses

likely are its high operating cost and

inflexibility. Newer power

technologies are designed to

eliminate these deficiencies and

provide substantial benefits,

including:

• Up to 25 percent end-to-end

efficiency improvements

40

7X24 MAGAZINE SPRING 2015

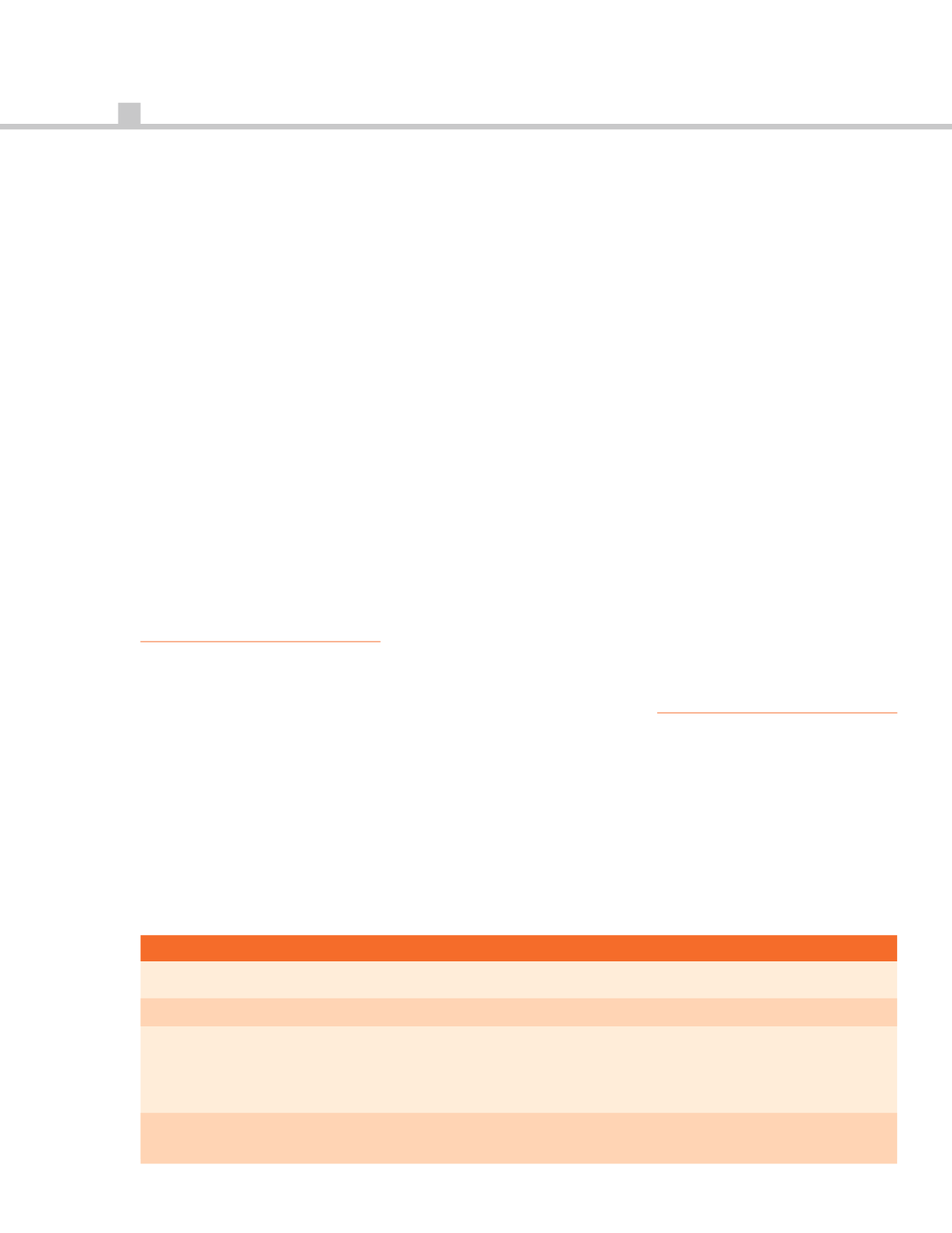

Annual Energy Cost

% Energy Savings

Annual Energy Savings $

$190,000

NA

NA

$133,000 -$123,500

30-35%

$57,000 - $66,500

$85,500 - $66,500

55-65%

$104,500 - $123,500

THE ANNUAL ENERGY BILL FOR THIS DATA CENTER IS $190,000, WHICH CAN BE CUT SUBSTANTIALLY:

Legacy system without improvements

First, add containment and increase

return air temperature 10° F. Then add

advanced controls to optimize airflow

and cooling capacity

Upgrade to New DX Technology with

Pumped Refrigerant Economization