65

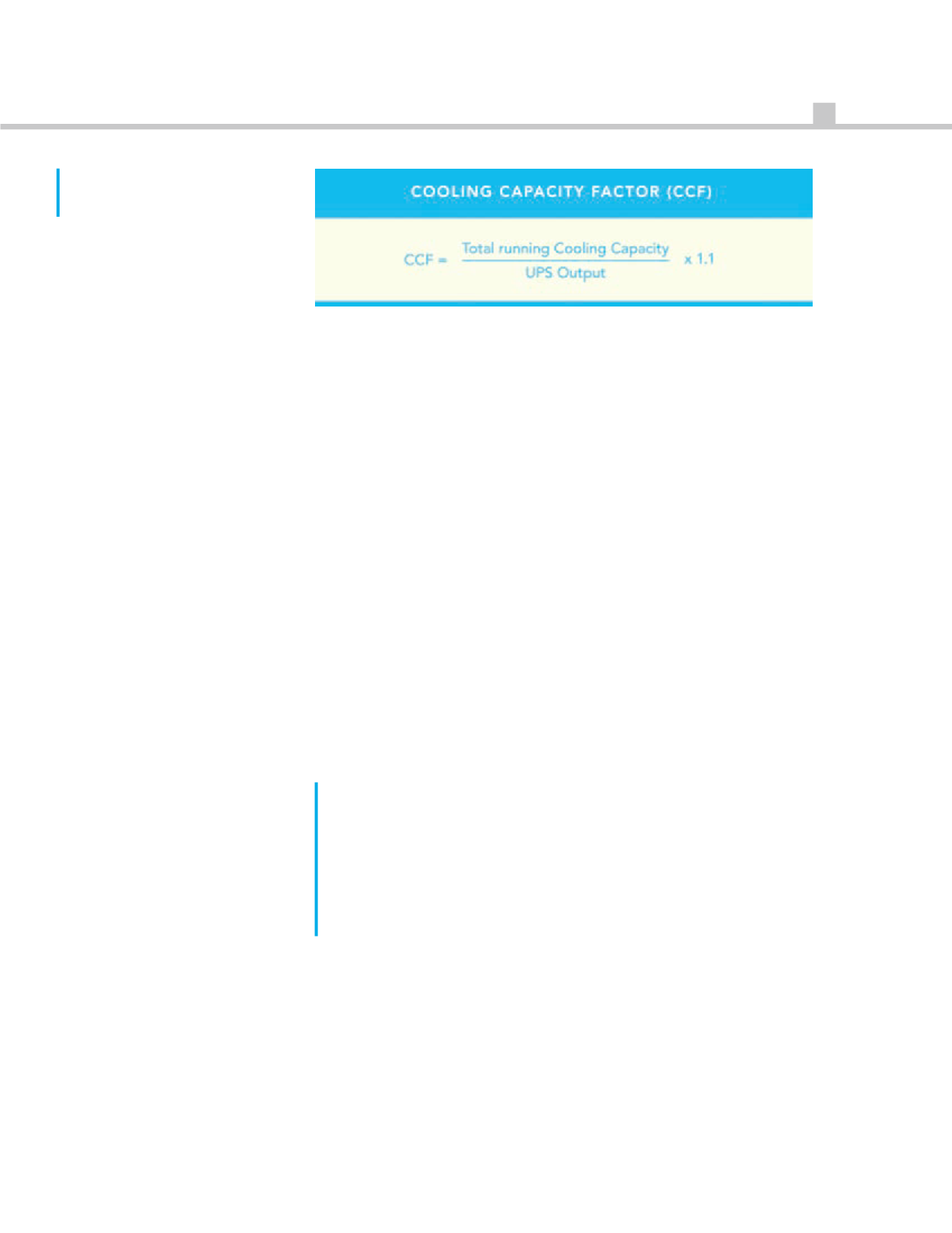

THE COOLING

CAPACITY FACTOR

The Cooling Capacity Factor is

calculated by dividing the total rated

cooling capacity (kW) by 110% of the

IT critical load (kW).

The total rated cooling capacity is the

sum of the running cooling units’ rated

capacities. If all cooling units are

running, then this will be the same

value as the total installed rated

cooling capacity. For example, if there

are 10 cooling units installed with a

rated capacity of 30 tons each and

seven are running, then the total

running cooling capacity is 739 kW (7

x 30 tons = 210 tons, 210 tons x 3.52

= 739 kW). To convert tons to kW,

multiply tons by the constant 3.52.

The IT critical load in the room is

equal to the Uninterruptable Power

Supply (UPS) output(s) for the room.

Ensure that the UPS output used is

only for the room being calculated. If

the UPS feeds other rooms, then those

loads must be subtracted from the

total UPS output. To account for

typical room load not reflected in the

UPS output, add 10% for lights,

people, and building envelope.

Cooling units are typically referred to

by the manufacturer’s stated capacity,

such as a 30-ton or 20-ton cooling

unit. If the manufacturer’s stated

cooling capacity is unknown, record

the model number on the cooling unit

nameplate and search online or call

the manufacturer.

It is important to know that the

manufacturer’s stated capacity refers to

the unit’s total capacity at standard

conditions, which refer to the

temperature and relative humidity of

the air returning to the cooling unit.

Typically, the standard conditions are

75° F (24° C) and 45% relative

humidity (RH). If the return air

conditions differ, the unit will have a

different cooling capacity. If the return

air is cooler and/or moister than the

standard condition, the unit will deliver

less than the stated capacity. If the

return air is warmer and/or drier than

the standard condition, the unit will be

capable of more than the stated

capacity.

Calculation of CCF uses the

manufacturer’s stated cooling capacity

because if the room layout is good

and airflow management (AFM) best

practices have been implemented

well, then it will be possible for the

unit to deliver at least the rated

capacity. However, in their current

state, many cooling units have a lower

return air temperature set-point than

the standard condition. The difference

between the delivered capacity at

current conditions and the potential

capacity at the standard condition, or

higher return temperature, is a form of

stranded capacity.

HOW TO INTERPRET

YOUR CCF AND

DETERMINE THE

AMOUNT OF

OPPORTUNITY AT

YOUR SITE

For rooms with a CCF of

1.0

to

1.1

,

there is little to no redundant cooling

capacity. It is critical that AFM

fundamentals be thoroughly

implemented in these rooms to make

available any redundant capacity and

keep IT intake air temperatures as low

as possible. It will likely be necessary

to install an additional cooling unit(s)

to have redundant capacity. AFM

improvements will likely improve IT

equipment intake temperatures and

create an environment where cooling

unit set-points can be raised, which

increases cooling unit efficiency and

capacity. However, there is no

opportunity to turn off cooling units or

reduce fan speeds.

For rooms with a CCF of

1.1

to

1.2

,

the number of running cooling units is

very closely coupled to the heat load

in the room. If IT intake temperatures

are not outside of the ASHRAE

recommended range then AFM

fundamentals have been thoroughly

implemented. There is approximately

one redundant cooling unit for every

10 units running. In some cases, this is

sufficient to maintain the room

temperatures if a cooling unit fails.

Cooling units should not be turned off

unless the room has 24-hour-by-

forever monitoring and staffing.

For rooms with a CCF of

1.2

to

1.5

,

there is moderate opportunity to

realize savings from turning off cooling

units or reducing fan speeds. This can

often only be done once AFM

improvements have been effectively

implemented. This does not require

full containment strategies, but does

require thorough sealing of raised

floor penetrations and open spaces in

racks, and best practice placement of

perforated tiles and grills.

A CCF of

1.5

to

3.0

is most common.

These rooms have substantial

opportunity to reduce operating cost,

improve the IT environment, and

increase the IT load that can be

effectively cooled. Rooms in this range

often have significant stranded cooling

capacity that can be released by

improving AFM.

WWW.7X24EXCHANGE.ORG