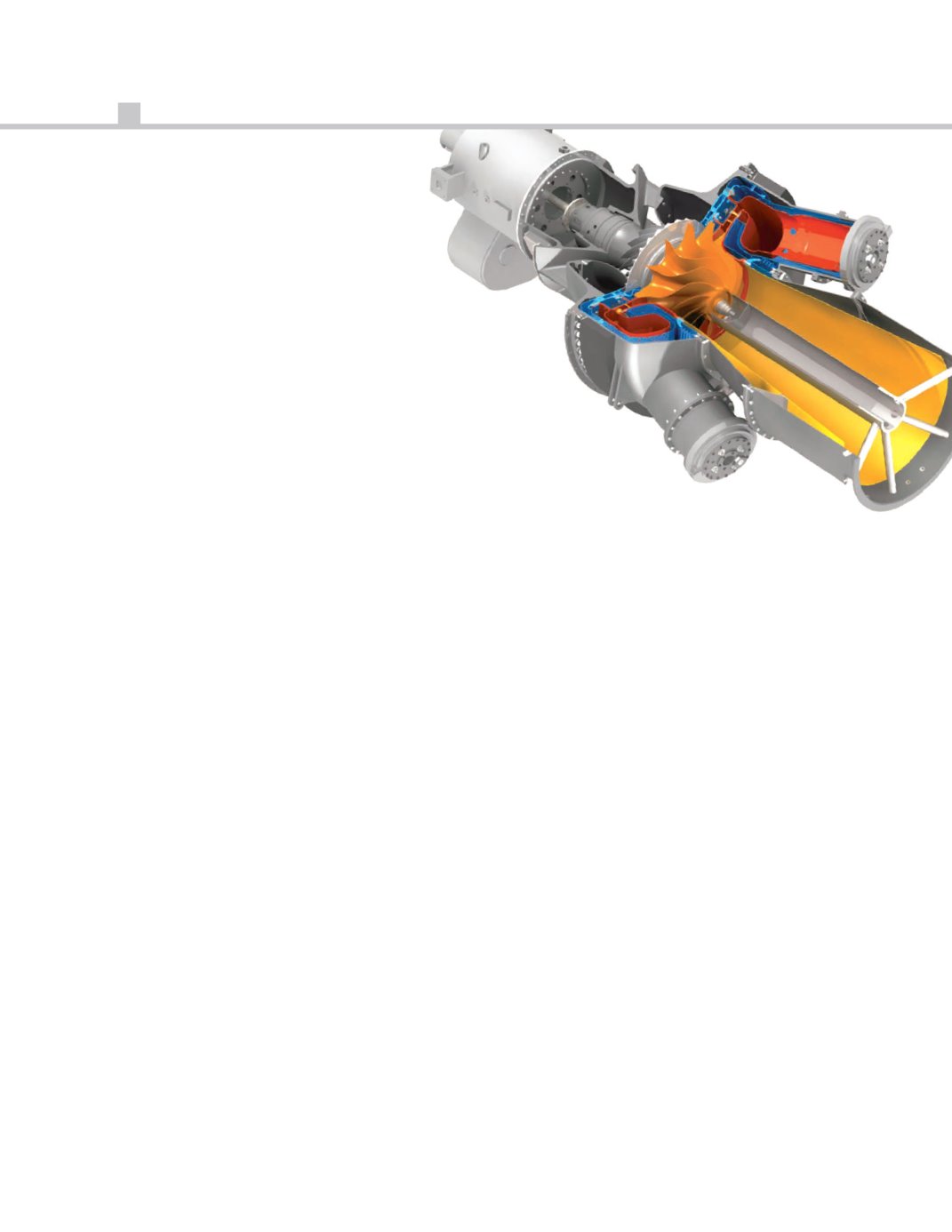

As the discretionary operation of

diesel generators becomes

increasingly restricted and the

recently announced Clean Power

Plan enters the implementation

phase, a pivot toward

cogenerated cooling from

resilient dual-fuel gas turbines

will become essential to the

boomer data center industry.

And radial gas turbines rated at

1.8MW are ideally designed for

data center applications.

Coupled with an absorption

chiller, a single turbine generator

displaces 2300kW of electric

power from the grid. But more

importantly, a dual-fuel turbine is

capable of smoothly switching

from 100% natural gas to 100%

diesel at full load without power

interruption in the event that the

utility gas supply is disrupted.

Such turbines can single-

handedly provide superior

reliability of prime electric power

and equipment cooling during

normal operation and in times of

emergency, reducing or

eliminating requirements for

backup diesel generators, UPS,

and associated maintenance.

Data centers are large power

consumers and heat producers,

requiring backup generators and

redundant cooling to qualify for

high reliability ratings. Diesel

generators sufficient to power

the electronics and electric

cooling (normally powered from

the grid) have been the standard

for data center standby power

due to their ability to startup

rapidly in the event of a power

outage. Uninterruptible Power

Supplies (UPS) bridge the gap to

maintain power during the ten

seconds it takes for the diesels

come on line. Despite tightening

restrictions on exercising diesel

engines for maintenance and

reliability checks, gas

reciprocating engines have not

displaced diesels. Gas engines

are slower to start and bring up

to full load, so they must be

accompanied by higher-capacity

UPS. Further, the probability of

gas supply disruption during a

major disaster results in

unacceptable system reliability

for the gas option. While some

gas generators can be operated

on diesel as well, they typically

required a minimum diesel flow

at all times, making extended

operation unacceptable unless

expensive emissions controls are

employed.

Enter the dual-fuel gas turbine,

capable of smoothly switching

from 100% natural gas to 100%

diesel at full load without power

interruption in the event that the

utility gas supply is disrupted.

The generator is operated 24/7

on 100% natural gas in parallel

with the grid, transitioning

seamlessly to island mode when

grid power is interrupted. In

order to maximize value during

normal operation, an absorption

chiller powered by turbine

exhaust provides continuous

equipment cooling to the facility.

Excess chiller capacity is

employed in a turbine inlet

cooling (TIC) system to boost

generator output.

by brent voelker

Fueling the inFormation economy:

ResilienT PoweR anD

CogeneRaTeD Cooling

74

7X24 MAGAZINE FALL 2015