26

7X24 MAGAZINE SPRING 2015

involves some trial and error. The

commissioning team often works with

the design / construction / vendor

team to troubleshoot issues

throughout commissioning.

Operators who have exposure to this

troubleshooting will benefit from a

better understanding of the

equipment, in addition to developing

valuable historical knowledge of what

has occurred prior to operation.

Additionally, it is an opportunity for

operations to start to develop

processes for future troubleshooting.

Relationships are often built during

the integration of a facility where

members of the design, construction,

commissioning and operations teams

are all working together. This can be

a stressful time but often the best

resources from many corners of the

team become evident during the

process. Technical resources in

equipment manufacturing

organizations, start-up technicians,

design professionals, and MEP

coordinators all can prove valuable

contacts to operations over the years

to come.

One of the first steps in learning is

recognizing what is normal and what

is not. During functional testing

commissioning teams stress the

systems to baseline the performance

and ensure that it works in a variety of

expected operating conditions.

Component and system anomalies

are expected during functional testing

where equipment operation is often

validated at design capacity. These

anomalies are very revealing in

demonstrating the consequences of

failure. As a result, facility operators

who have witnessed and participated

in these evolutions are much better

prepared to respond to issues once

the facility is serving live traffic.

Participating in this phase provides

the base of knowledge that facility

operations will need for the

development of emergency operating

procedures. Having access to, and

knowing how to perform these

procedures can dramatically minimize

the impact of outages.

In addition to improving notification

and response time, monetary value is

realized by making adjustments with

an understanding of what is or is not

a truly service affecting event.

Examples of this include what spare

parts are maintained on hand, how

service agreements are established,

and how sites are staffed.

Levels 4 and 5 commissioning are the

beginning, but not the end of

integration and optimization. Many

data center owners encourage, if not

expect, continuous improvement in

this dynamic environment.

Improved reliability, energy

conservation, and adoption of new

technologies for efficiency gains are

often a part of an operations team’s

objectives. Participating in

commissioning provides operators

with a base of knowledge that allows

them to better recognize those

opportunities for continuous

improvement.

CONCLUSION

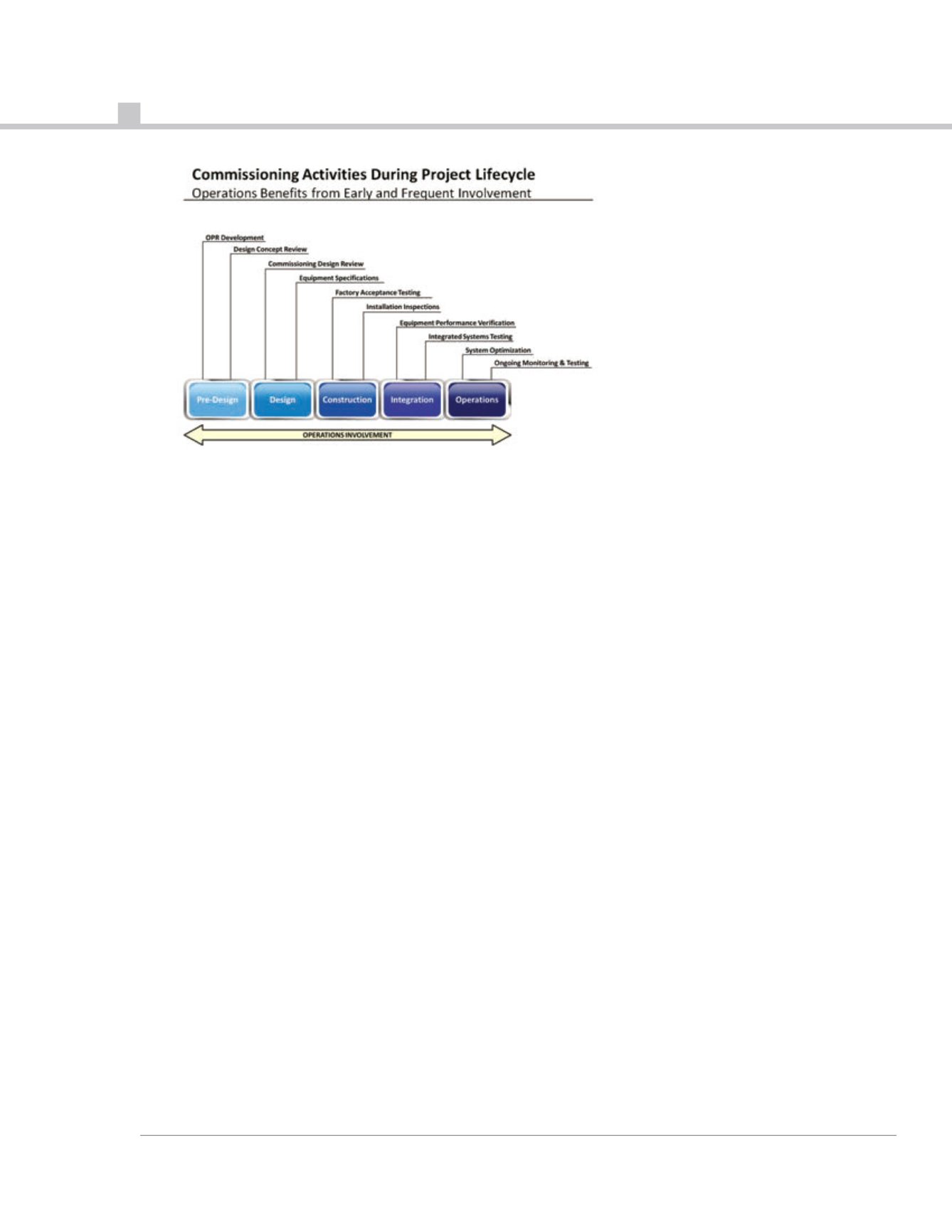

Commissioning agents and data

center design build departments

should consistently encourage

participation by facility operations

with engagement beginning in the

planning stages of their projects.

For this to be successful, facility

operations teams have to make the

time to participate in the process.

Doing so requires support from the

organization which is easily justifiable

considering the significant payoffs.

The majority of data center outages

are the result of human error. A

critical aspect of providing operations

with the tools they need, begins with

their active involvement in

commissioning.

When integrated into the

commissioning process, data center

organizations consistently find their

operations teams are more proactive

in responding to abnormal or

emergency situations and more

effective in the day-to-day operation

of the facility.

All of this is achievable with relatively

little additional effort by simply

defining the requirements up front

and ensuring thorough planning.

Brian Durham is the Vice President of Field Services for DLB Associates Consulting Engineers. He can be reached at

[email protected]